modusAOI Sense3D

modusAOI Sense3D is a multi-camera light-field based 3D AOI system featuring a unique modular construction and a one-of-a-kind approach to 3D inspection.

Each Sense3D module contains three high-resolution color cameras, whose data is processed in parallel on a high-performance FPGA and transferred via a high-speed 10 Gbit/s connection. In combination with a flat and compact design, this enables the system to be adapted to a large range of different applications while delivering constant high performance.

Sense3D features state-of-the-art algorithms for 3D computation and analysis, delivering parallax-free images and high-quality 3D data for large scan areas without compromising acquisition time. As Sense3D uses the same well-known and proven modusAOI software package as other modus AOI systems, no additional training is required to take advantage of its extended feature-set and capabilities.

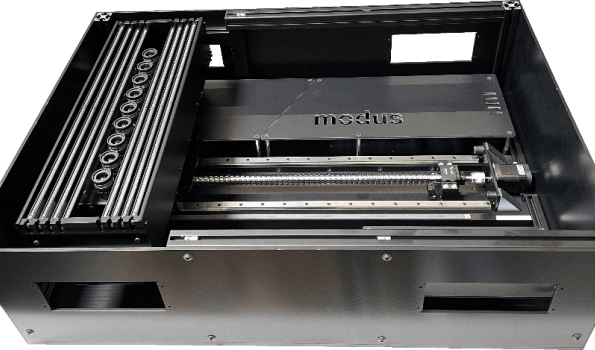

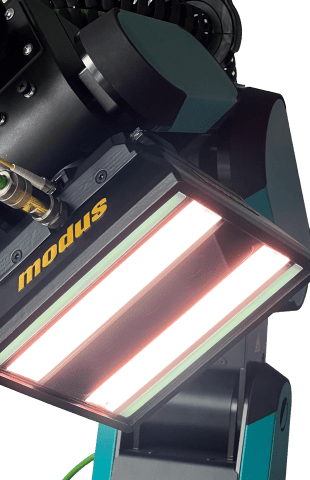

At launch, Sense3D will be available in a three-module flatbed scanner variant with a total of nine cameras and a single-module variant with three cameras for highly flexible use in conjunction with a robot arm. The Sense3D Scanner variant uses the same housing as the popular modus S3 AOI scanner-system, allowing for a drop-in replacement if the upgrade to a 3D AOI is desired. Due to its light weight and compact size, the Sense3D robot variant can be employed in almost any configuration, easily making it one of the most adaptable AOI systems on the market.

Features

- Camera system for inspection of objects in 3D

- Multi-camera-array for light-field-based 3D computation

- Modularized hardware architecture allowing for flexible adaptation to inspection task

- Each module contains:

- 3x high-resolution 16 MP Type 1.1 Sony CMOS sensor

- Highly specialized FPGA technology for parallelized 3D computation

- 10 Gbit/s Ethernet connection for extremely fast transfer speeds

- Single module variant (3 cameras) for maximal flexibility, mounted on a robot arm

- Tripple module variant (9 cameras) for full-frame scan area, mounted in a flatbed scanner

- Polarized lighting unit for reflection-free imaging, including UV light for coating detection

- State-of-the-art algorithms for calibration and 3D data fusion

- Parallax-free images generated via sophisticated processing from 3D data

- Well suited for most 2D and 3D inspection tasks

- Flat, compact design

- Easy installation

- Low maintenance

- Adaptable precision depending on speed requirements

- Scanner variant interchangeable with modusAOI S3 scanner (same housing)

- Uses well-known modusAOI software

- No additional training required

- One software tool for all applications

- Flexible adaption to different applications

Technical Specifications

| Sense3D Scanner variant | Sense3D Robot variant | |

|---|---|---|

| Image Sensor | Sony IMX542-AAQJ 16.2 MP (5328x3040) Type 1.1 CMOS Up to 52.6 fps 2.74 x 2.74 µm pixel size Up to 12 bit color depth Global shutter |

|

| Number of image sensors | 9 | 3 |

| Number of modules | 3 | 1 |

| Total data per scan | >20 GB | 0.4 GB per robot position |

| FPGA for depth processing | 3x Xilinx Artix Ultrascale+ | 1x Xilinx Artix Ultrascale+ |

| Transfer speed | 3x 10 Gbit/s | 10 Gbit/s |

| Lighting | White, red, blue (all polarized) and optional UV | |

| Lens | 1:2.6, f=12mm, C-mount | 1:2.6, f=12-25mm, C-mount |

| Inspection area | 420x650mm | Any depending on robot movement |

| Lateral image resolution | 600-2400dpi=10-42µm/px | Depends on lens / working distance |

| Working distance | 130-170mm | Any depending on robot movement |

| Captured depth range | Up to 22mm | Depends on lens / working distance |

| Depth resolution | Up to 9µm³ | Depends on lens / working distance |

| Minimal clearance required | 80mm | Depends on working distance |

| Full inspection speed | <25sec incl. full test Less for smaller scan area |

Depends on number of images <0.6sec per image |

| Dimensions and weight | 528x181x149mm, 7.5kg (head only) 860x610x251mm, 52.6kg (full scanner unit) |

126x116x116mm, 1.4kg (head only) 222x194x120mm, 2.7kg (with light unit) |

| Power | 230V/50Hz P1 or 110V/60Hz | |

| Additional features | Intuitive test plan generation, supported by AI Multiple views for test specimen on object Real 3D visualization of object and test results Automatic 3D PCB unwraping (3D Fiducials) Automatic alignment correction of images State-of-the-art camera calibration Interfaces for traceability and MES connection |

|