Description

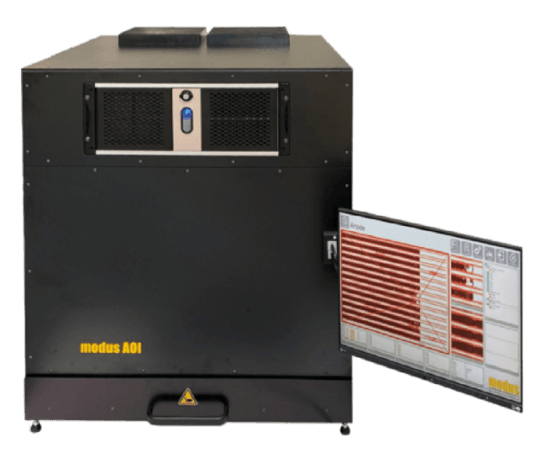

The almost maintenance-free modusAOI MCS42 camera system was developed specially for transport modules in production lines – and also comes in an offline version. Existing production lines can easily be retrofitted with this system.

The system comes with four 42 megapixel cameras and a high-performance control unit. LED lighting, including LED control, is also included in the delivery. The entire picture of the image analysis is orthogonally calibrated.

Inspection with the high-resolution system cameras is carried out using the tried and tested modusAOI software. Our production process is certified under ISO 9000 and also includes a CE Declaration of Conformity. The system has been adapted to the high requirements of the inspection of bipolar plates. The image acquisition time of approx. 2,5 seconds with a resolution of 24 um is outstanding.

Advantages

- Easily integrated

- Cost-effective

- Easy to use

- Minimal training required

- No slip, few pseudo-errors

- Calibratable system

- Stable test precision

Test possibilities

- Position and minimum thickness of the graphite coating in the central area

- Position and minimum thickness of the screen print at the edge of the workpiece

- Checking the surface that should not be coated

- Coating contamination (graphite/screen print)

- Coating mass may only be on the beading tops

- Testing of a defined target contour in screen print

- Constrictions in coating path

- Small blisters in coating path

- Damage to the metal at the edge (balcony) of the workpiece

- Position of the anode-cathode connection (offset)

- General damage such as deformation and scratches

Features

Camera unit C42

- Resolution 4 x 42 megapixels =168 megapixels (21456 x 7716 pixels) aspect ratio 2:3 per camera

- RGB colour filter from CMOS sensor, colour intensity 24 bit

Light source

- LED cluster white and red

Lens

- 1:1,4 - 25 mm, Objektiv (C-Mount)

Field of view

- default FOV: 450x180mm, Customized FOV possible

Test speed

- image acquisition ~2,5 seconds, processing time (during handling) ~7 second

System PC

- Intel i9-10980XE (12-core) 3.5 GHz, 64GB DDR4-RAM, 2 x 1 GB/s network interface,

- I/O modules, 1 x 1 TB NVMe SSD, 2 x 4TB NAS HDDs, Windows 10

- Professional/LTSC 64 Bit, Acronis backup software, keyboard, mouse, operator, keyboard, 24” full HD IPS 16:9 monitor

Dimensions

- Camera unit (L*B*H): 39 x 39 x 40 mm

- AOI box (L*B*H): 829 x 788 x 1011 mm

Connected values

- 230 V / 50 Hz P1 or 110 V / 60 Hz

- Consumption: 300 W

Options

- Seamless stitching of 4 camera images (combined for one test plan)

- Automatic start by closing the drawer (offline system)

- DMC Code automatically detected

- Customer-specific software development